In the realms of science, engineering, statistics, and even daily life, two terms often arise: reliability and precision. While they may seem interchangeable at first glance, they embody different concepts that are crucial in their respective fields. Reliability refers to the consistency of a measurement or test, while precision denotes the exactness of the results produced. Understanding the subtle differences between these terms can significantly impact decision-making processes, data interpretation, and the overall quality of outcomes.

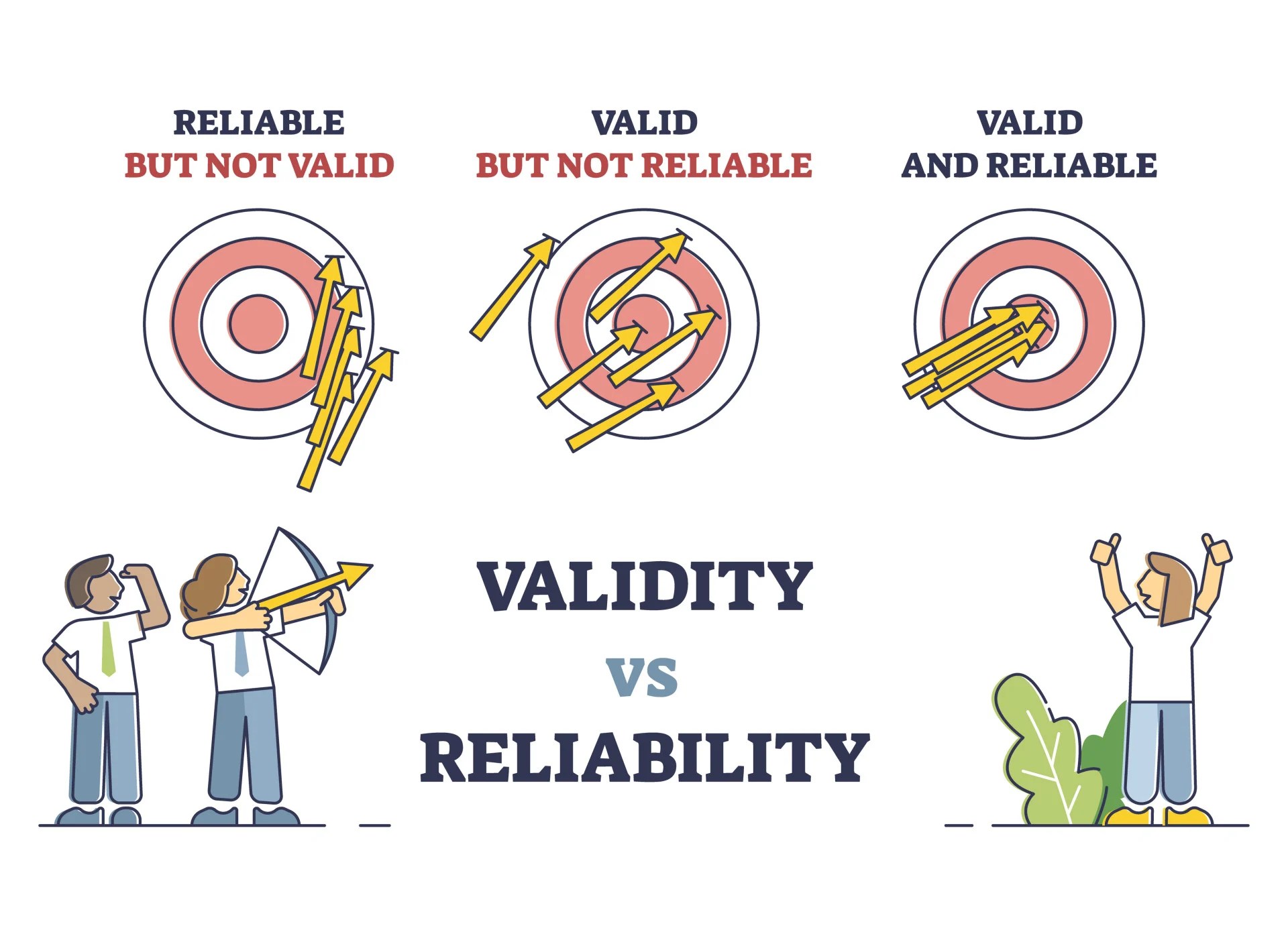

When discussing reliability vs precision, it is essential to grasp how these concepts interrelate and how they can affect the outcomes of various processes. For instance, a measurement can be highly precise but not reliable if it consistently yields the same inaccurate result. Conversely, a reliable measurement might not be precise if it varies significantly with each trial but still centers around a true value. This distinction can have profound implications in fields such as quality control, research, and even personal decision-making.

The significance of understanding reliability vs precision extends beyond technical definitions. In everyday scenarios, individuals often encounter situations that require them to assess the reliability and precision of the information they receive. Whether evaluating a product's quality, interpreting research findings, or making significant life choices, recognizing the differences and interconnections between reliability and precision can foster better judgments and outcomes.

What is Reliability?

Reliability refers to the degree to which an assessment tool produces stable and consistent results. It is an essential component in determining the quality of a measurement process. Reliability can be assessed in various ways, including:

- Test-retest reliability: Consistency of results when the same test is administered at different times.

- Inter-rater reliability: Agreement between different raters or observers measuring the same phenomenon.

- Internal consistency: The degree to which items on a test measure the same construct.

Why is Reliability Important?

Reliability is crucial in numerous domains, including research, healthcare, and quality assurance. The implications of unreliable data can lead to:

- Misleading conclusions: Inaccurate interpretations of research findings can result in flawed decisions.

- Increased costs: In industries such as manufacturing, unreliable processes can lead to waste and inefficiencies.

- Loss of credibility: Inconsistent results can diminish trust in a brand, organization, or research institution.

What is Precision?

Precision, on the other hand, measures how close the results of repeated measurements are to one another, regardless of whether they are close to the true value. Precision is characterized by:

- Low variability: The extent to which repeated measurements yield similar results.

- Granularity: The level of detail in the measurement process.

- Significant figures: The digits in a number that contribute to its precision.

Why is Precision Important?

Precision is vital in situations where exact measurements are critical. In fields like engineering, medicine, and scientific research, precision can lead to:

- Improved accuracy: Precise measurements can enhance the accuracy of results.

- Better replicability: High precision allows for experiments to be replicated with confidence.

- Enhanced product quality: In manufacturing, precision ensures that products meet strict specifications.

How Do Reliability and Precision Interact?

While reliability and precision are distinct concepts, they often interact and influence each other. A measurement can be reliable without being precise, and vice versa. Understanding this relationship is crucial for accurate assessments. For example:

- A reliable measurement tool provides consistent results, but those results may not be close to the true value.

- A precise measurement tool yields results that cluster closely together but may consistently miss the true value.

Can a Measurement Be Reliable but Not Precise?

Yes, a measurement can be reliable without being precise. For instance, if a scale consistently weighs an object at 5 kg, but the true weight is 7 kg, the scale is reliable but not precise. In this scenario, the results are consistent but not accurate, demonstrating the importance of evaluating both reliability and precision in measurement processes.

Can a Measurement Be Precise but Not Reliable?

Similarly, a measurement can be precise but not reliable. Consider a thermometer that consistently reads 30°C for a boiling water sample, which should be 100°C. The thermometer is precise because it produces the same result repeatedly, but it is not reliable because it produces an incorrect measure of the temperature. This emphasizes the need for verifying both reliability and precision before drawing conclusions from any measurements.

How to Improve Reliability and Precision?

Improving reliability and precision requires a systematic approach, including:

- Calibration: Regularly calibrating measurement tools ensures they provide accurate results.

- Standardization: Adopting standardized procedures can enhance consistency across measurements.

- Training: Providing adequate training to personnel involved in data collection can reduce variability and errors.

Conclusion: Navigating the Landscape of Reliability vs Precision

In conclusion, understanding the differences between reliability and precision is essential for accurate measurements and informed decision-making. While both concepts are vital in various fields, recognizing their unique attributes and interrelationships can help individuals and organizations optimize processes and improve outcomes. Whether in research, engineering, or everyday life, being equipped with the knowledge of reliability vs precision can pave the way for success and better quality results.

Exploring The World Of Italy Cockroaches: Myths, Facts, And Management

Exploring The Rich Tapestry Of Canterbury Tales Characters

Unraveling The Mystery Of Gimbels' Closure